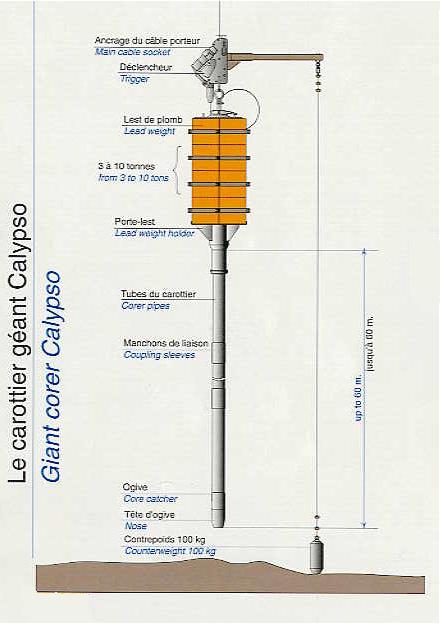

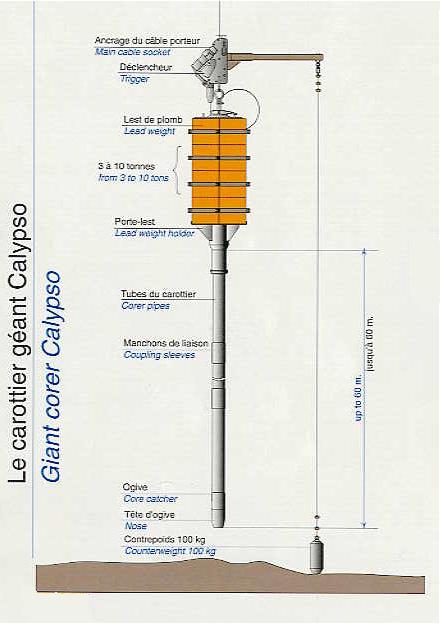

Figure 1: Components of the Giant Corer Calypso

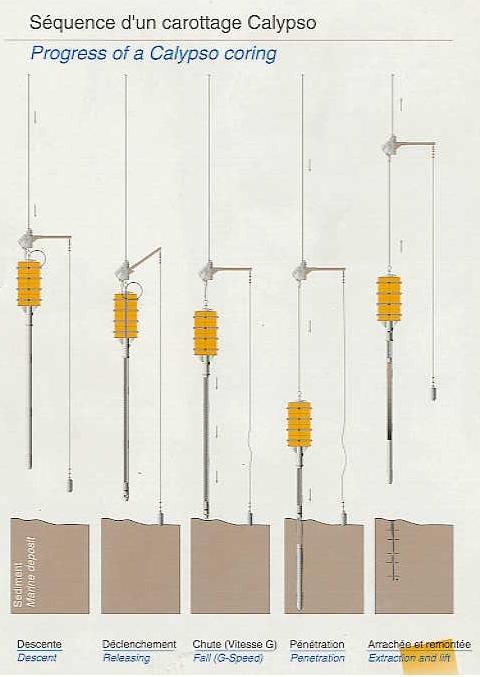

To understand how Calypso works it is very important to notice the components of the corer shown in Figure 1. The corer consists of a trigger (piston), weight (~7 tons), corer pipes (metal tube with transitions), core catcher and four cables: main cable (from the corer to the ship), counterweight cable and the connecting cable between the corer tube and the piston (extra cable showed in top of the weight),i all of which are shown in Figure 1.

After the giant corer Calypso is extracted from the sea, the marine sediment sample is in a plastic pipe, called a liner, inside the corer pipes. This liner is extracted and cut it into pieces of 1.5 m long and labeled. Each one of the 1.5 m samples are cut horizontally into two pieces. One of the two pieces is used for archiving and the other is used to do the measurements needed. The sample will be scanned to get an image before the sample is analyzed. The general properties of the sediments will be measure by the Multi System Track (MST), which measures p-wave velocity and amplitude, density, impedance and magnetic susceptibility. After the general properties are determined the core sample is cut it into stratigraphic sections depending the age of the sediments.

Storage of coring pipes. |

Bringing the core back. |

The core on board (after extracting the PVC pipe from the casing). |

Control desk of the coring system. |

Rolls of kevlar cable. |

Winch for the kevlar cable. |

Kevlar cable coming out on the back deck. |

Kevlar cable out to sea... |

Bringing the pipe onboard |